DISTILLATION KIT FOR ESSENTIAL OILS

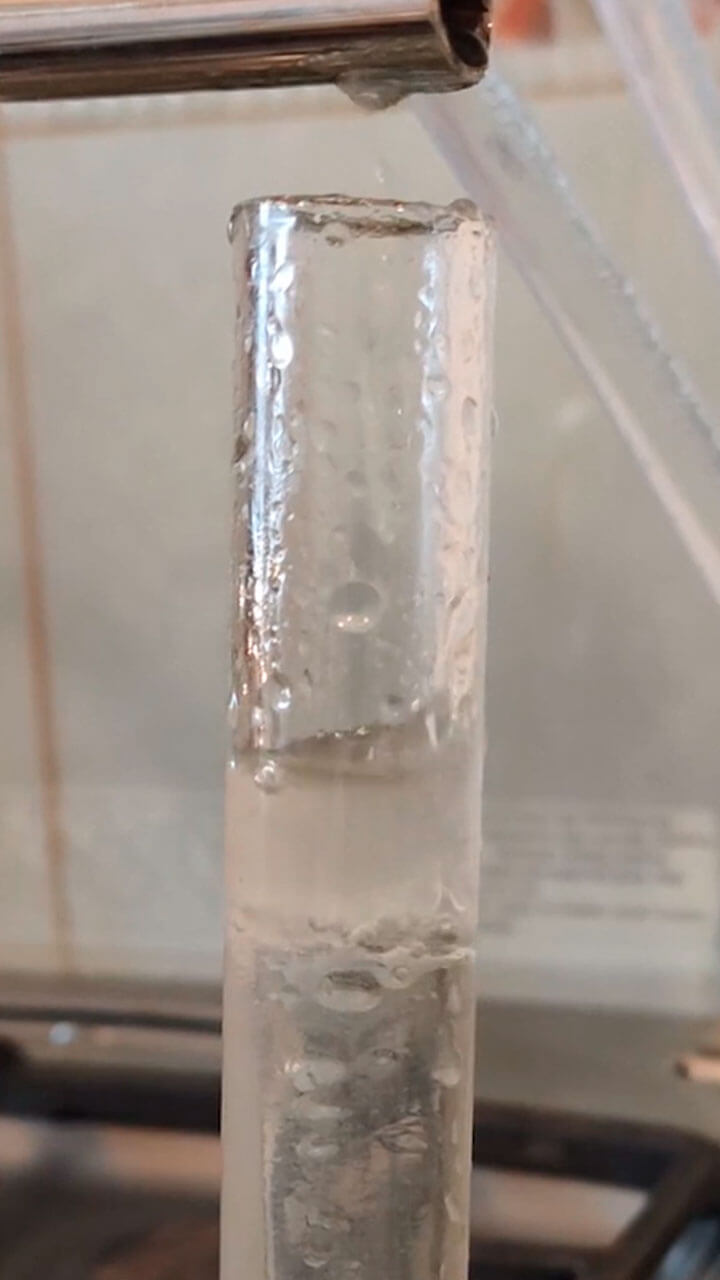

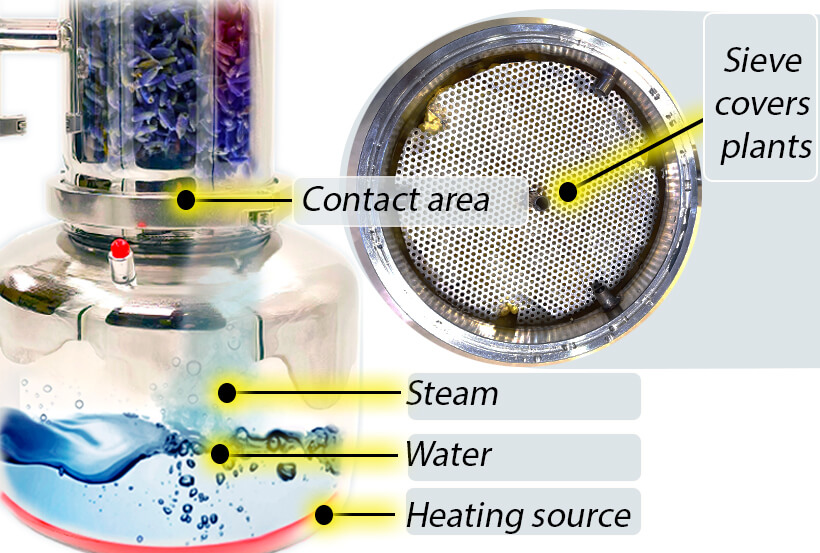

Steam distillation has been in use for essential oil extraction for many years, which is carried out by passing steam through the biomass(plant material) whereby the steam volatile compounds are vaporized, condensed and collected in the receiving flask.